Inside the University of Saskatchewan’s Vaccine and Infectious Disease Organization

Home to one of Canada’s only Level 3 biosafety labs, VIDO was one of the first in the country to isolate SARS-CoV-2.

Through a thick glass window in her office, Alyson Kelvin watches a colleague wearing a white hazmat suit, nitrile gloves and booties. A battery-powered waist pack blows pure, filtered air into the woman’s helmet through a tube on her back as she puts down her pipette, analyzes the tray, then washes her slide several times to see how many antibodies still cling to the spike protein of the SARS-CoV-2 virus sample she’s working on.

A virologist who focuses on influenza, respiratory viruses and the way immune systems respond to them, Dr. Kelvin has spent enough time in the Level 3 biohazard containment lab on the other side of the glass that she routinely wears three layers to work. “I get really cold because it’s a lot of blowing air,” she says, smiling as she wraps a shawl around her shoulders, waiting for a Zoom meeting to begin on her computer screen.

Back in early 2020, when news reports began to surface about dozens, then hundreds of people in China being hospitalized with an undiagnosed pneumonia, Dr. Kelvin was in Halifax, doing viral research sponsored by the U.S. government. As she watched Beijing desperately trying to contain the infections, she made a life-changing phone call. “I knew we were on the verge of something,” Dr. Kelvin remembers. “We had to get working immediately.”

The person on the other end of her phone call was Volker Gerdts, director and CEO of the Vaccine Infectious Disease Organization (VIDO) in Saskatoon. Soon Dr. Kelvin was on her way west, planning to stay in Saskatoon three weeks while her family remained in Halifax. After returning home, she watched in frustration in mid-March 2020 as her laboratory at Dalhousie University shut down because of a ban on in-person research during the first few months of the pandemic.

Meanwhile, VIDO managed to isolate the SARS-CoV-2 virus, the first lab in Canada to do so. Dr. Gerdts called the entire staff together. It was all hands on deck, he told them. They would be working flat out on this new virus for the foreseeable future. Dr. Kelvin knew she had to be part of that effort. She began arranging to relocate her family to Saskatoon later that spring so that she could join VIDO (where she now runs her own research group).

“Through COVID alone, we’ve now worked with almost 100 companies. We really ramped it up and gave all these companies access to our facility, meaning we did the work for them.”

Dr. Gerdts was being flooded with calls from drug researchers to test their prototypes, as the scientific world launched anti-coronavirus therapies and vaccines with varying degrees of success. He soon realized he needed 30 more staff, who would all need up to six months of training before they would be cleared to work in VIDO’s high-security labs. “Through COVID alone, we’ve now worked with almost 100 companies,” Dr. Gerdts says. “We really ramped it up and gave all these companies access to our facility, meaning we did the work for them.”

A German-born immunologist and vaccine scientist, Dr. Gerdts first arrived at what was then dubbed the Veterinary Infectious Disease Organization back in 1997, for a postdoctoral fellowship. He specialized in creating neonatal vaccines until he was hired three years ago to lead VIDO, home to one of Canada’s only Level 3 biosafety labs, meaning it’s authorized to handle deadly pathogens, like anthrax.

The organization’s staff includes scientists from 25 countries, who conduct independent research and are also contracted to test vaccines, anti-viral compounds and therapeutics for pharmaceutical companies around the world. While many vaccines and treatments never make it to the finish line, VIDO’s data quietly led to the creation of at least one effective COVID-19 vaccine that’s been approved outside North America, along with other immunotherapeutic antivirals. The pandemic also pushed VIDO’s scientists to create their own COVID-19 vaccine candidate, despite formidable challenges.

‘A game changer’

One of the keys to VIDO’s success lies on the east side of the University of Saskatchewan campus, nestled between grain bins, satellite dishes and the bovine teaching unit at the Western College of Veterinary Medicine. During a recent visit to the facility, a group of young women in coveralls strolled past on their way to nearby dairy barns. The few windows on the unassuming four-storey silver building are dwarfed by black slatted ventilation systems that stretch more than 40 feet wide and 20 feet tall. Inside the 180,000-square-foot laboratory, veterinarians care for dozens of different species, including bats, alpacas and sheep.

First established in 1975 as an offshoot of the U of S veterinary college, VIDO’s researchers initially focused on treating zoonotic and animal-borne diseases, creating successful vaccines and therapeutics for respiratory, gastrointestinal and hemorrhagic diseases in cattle, poultry and swine. “This was a game changer for livestock producers in Canada,” recalls Paul Hodgson, VIDO’s associate director of business development. Their first cattle vaccine, Vicogen, dramatically reduced calf mortality. It was created in collaboration with Connaught Laboratories, the federally owned vaccine facility that was later privatized and eventually became Sanofi Pasteur years later.

As privatizations and corporate mergers swept Canada’s pharmaceutical sector, VIDO’s commercial animal vaccine production company, Biostar, was sold to American pharmaceutical manufacturers, with its vaccines going to Novartis Animal Health. Still, the national laboratory remains owned by the federal and provincial governments, through the U of S. The organization has fought for federal and provincial grants to expand over the past two decades, and is now embarking on a mission to become a national centre for pandemic research. “A lot of the animal diseases, true animal diseases, became good models for human diseases,” Dr. Hodgson says. “A lot of the pathogens move across species.”

So in early 2020, as the global health emergency worsened, a dozen staff members worked late into the night in between contract jobs to

create one of VIDO’s first human vaccines, backed at first with $1 million in federal funding. The vaccine was pioneered by Darryl Falzarano, a virologist who has worked with Ebola and Zika, and who became the first scientist in Canada to isolate SARS-CoV-2 in February 2020. For years, Dr. Falzarano worked at vaccinating animals carrying another corona-virus — the one that causes Middle East Respiratory Syndrome (MERS). That virus causes an upper respiratory tract infection, which doesn’t bother the camels carrying it — but does spread to humans. It causes fever, cough, shortness of breath, and moves quickly, killing a third of the people it infects.

With camels in short supply on the Canadian prairies, Dr. Falzarano went into the pandemic having already created two vaccines that prevent coronavirus transmission in alpacas. “At the beginning, we worked as much as we could possibly work,” Dr. Falzarano says. He remembers logging as many as 95 hours per week – but the effort paid off. Using their knowledge of the MERS coronavirus, in just five weeks his team was able to identify a candidate antigen and produce a COVID-19 vaccine that worked in ferrets.

But adapting it for humans was another story. VIDO was the first organization at a Canadian university to enter its vaccine in clinical trials, competing with established biopharmaceutical companies and deep-pocketed American and European companies that were pushing forward with MRNA technology. “We did not receive a billion dollars in ‘Warp Speed’ funding,” says Trina Racine, VIDO’s associate director of vaccine development, referencing the US$18 billion dollar program that was underway in the United States. “We don’t have tens of thousands of employees.”

And while VIDO was making headway hiring more researchers, the excitement of its initial vaccine breakthroughs was giving way to frustration. The Canadian-made vaccine worked well enough in hamsters, but now scientists had to create test doses for humans. By the summer of 2020, staff found themselves shopping around for both vaccine components and a manufacturer with enough time and capacity to produce a small batch. Dr. Racine says that caused an “incredibly frustrating” six-month delay in the development of VIDO’s vaccine, called COVAC-2. (Researchers were also working on a second formulation, called COVAC-1, which is mixed with a different adjuvant.)

Lab staff were also starting to burn out. One returned home to China, having not seen her family in more than two years. Another left for Toronto after being recruited by Sanofi Pasteur, which was eager to offer a full-time, higher-paying job to someone with experience at VIDO’s Level 3 labs. “You’re losing people when you need people the most,” says Dr. Falzarano. “Then you’re bringing in new people and training them, but it takes a while.”

Despite the many hurdles, VIDO announced encouraging interim results from Phase 1 clinical trials for COVAC-2 in June. “We demonstrated that the vaccine is safe,” says Dr. Gerdts. “Volunteers had immune responses that are comparable to Moderna or Pfizer.” In addition, he says, COVAC-2 doesn’t require ultra-low temperature storage, which makes it a solid choice for remote and Indigenous communities in Canada, as well as for millions of people in low and middle-income countries.

But expanding those human trials is also proving to be tricky. After its initial call for volunteers, VIDO was flooded with calls from unvaccinated Canadians who wanted to sign up. Dr. Racine says a number of volunteers said they felt better about VIDO’s vaccine candidate because it used the same protein subunit technology as whooping cough, polio, tetanus and other traditional vaccines. For ethical reasons though, during a pandemic Health Canada does not allow traditional vaccine trials that are designed with a placebo group. One result is that VIDO will have to delay its Phase 2 Canadian trials well into 2022 in order to find enough already-vaccinated volunteers who can take COVAC-2 as a booster.

That led Dr. Racine to reach out to colleagues in Senegal and Uganda, countries where only around five per cent of the population is fully vaccinated. After recruiting 300 volunteers, VIDO has been aiming to begin Phase 2 clinical trials in those countries. Dr. Racine hopes they will be able to bring the cost per dose down to $3. She estimates the MRNA vaccines Canadians receive cost closer to $20 per dose.

Manufacturing bottleneck

Another major challenge VIDO’s scientists have encountered is a lack of manufacturing capacity. In mid-2020, as vaccine candidates were emerging, Canada found itself flat-footed, with no domestically owned pharmaceutical companies that could produce enough doses for the country. Ottawa had promised to spend $2.2 billion to ramp up domestic vaccine manufacturing capability, to ensure it could weather the next pandemic. The federal government then signed large contracts for offshore vaccines, purchasing more doses per capita than any other country. Once a majority of Canadians were eventually vaccinated, the simmering anger over the lack of domestic vaccine production faded. By the fall election in 2021, all major party platforms supported Canadian vaccine production on paper, but few candidates or leaders ever spoke of it.

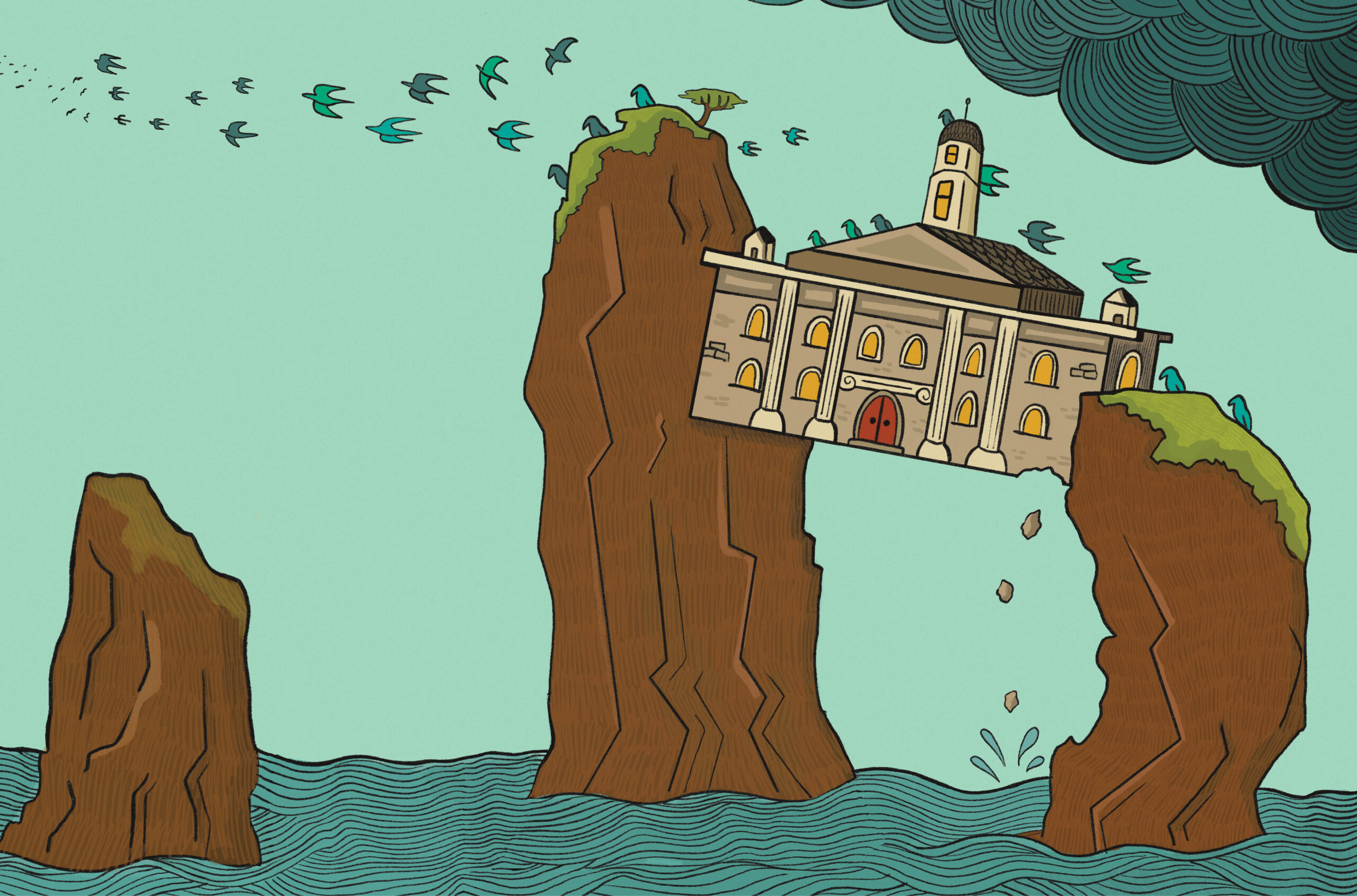

VIDO has been trying to build its own small-scale vaccine manufacturing plant for a decade. Until the pandemic, its lobbying efforts had secured only “a few million dollars,” which was far from enough, according to Dr. Gerdts. With SARS-CoV-2 spreading around the world, the same people in Ottawa who had turned him down a year earlier were now asking how soon the organization could have a manufacturing plant up and running. Dr. Gerdts had to tell them there was no way it could happen overnight. Instead, VIDO had to rely on other companies “to fit you in their schedule,” he says, likening the process to trying to build a car with parts from dozens of different factories rather than building a vehicle in a single location.

“It will be one of the few places in the world that can make both human and animal vaccines under good manufacturing practices in the same Level 3 facility.”

In the 2021 federal budget, Ottawa earmarked $59 million to further VIDO’s strategic initiatives, which include establishing the organization as “Canada’s Centre for Pandemic Research.” Along with private donations and just over $15 million in municipal and provincial support, the idea is to upgrade some of VIDO’s laboratories to Level 4 containment and upgrade its animal-holding facility. This $66 million infrastructure enhancement should be completed over three years. The animal facility will house a wide range of animals including bats, insects and other exotic species.

In addition, VIDO’s biomanufacturing facility will create small batches of vaccines and biologic products for testing. “It will be one of the few places in the world that can make both human and animal vaccines under good manufacturing practices in the same Level 3 facility,” says Dr. Hodgson.

Alan Bernstein, a vaccinologist, president and CEO of the Toronto-based global research organization CIFAR, and a member of Canada’s national vaccine task force, believes any vaccine manufacturing facilities should be “intimately tied” to universities, where most fundamental scientific research is taking place. To that end, he says VIDO and the U of S together can play a “really critical” role in ramping up Canada’s capacity to develop homegrown vaccines. “VIDO has a golden opportunity to use its base of animal vaccinology to expand into human vaccinology,” he says. “It’s not a huge leap.”

Earl Brown, a virologist and professor emeritus at the University of Ottawa, agrees. He says that when it comes to animal-borne infectious diseases, VIDO is now “probably positioned much better than other [entities] in Canada, unless you count GlaxoSmithKline and Sanofi Pasteur, and those are big multinationals.”

Drs. Brown and Bernstein both say Canada has taken steps in the right direction to be more prepared for pandemics, but more still needs to be done before the next one hits, which they believe will likely be within the next decade.

VIDO is keen to see its scientists play a leading role in that process. But Dr. Gerdts still worries about holding on to the expertise the organization has built up, and enabling staff to react as quickly as possible to future virus threats. It costs $10 million each year to keep the lights on, to feed and house the animals, and to pay the scientists working with them. Yet he compares their work to that of emergency responders. “You cannot, when you have a fire, start looking for fire trucks or firefighters,” Dr. Gerdts says. “You need to be able to respond rapidly.”

Post a comment

University Affairs moderates all comments according to the following guidelines. If approved, comments generally appear within one business day. We may republish particularly insightful remarks in our print edition or elsewhere.